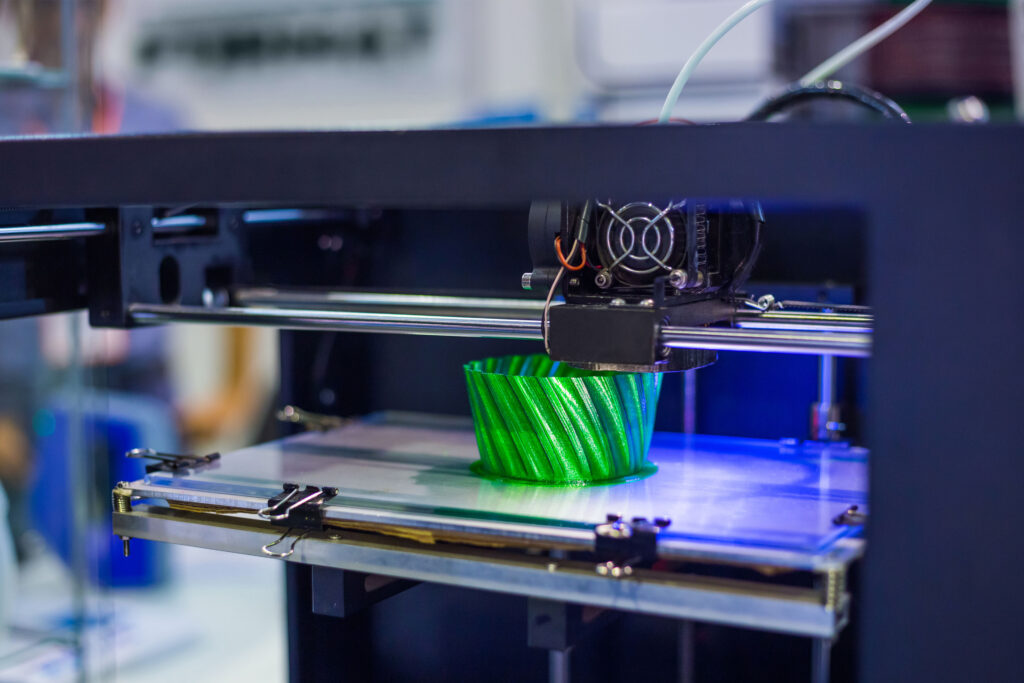

In today’s fast-paced world, businesses are seeking faster, more cost-effective ways to create custom products. Whether it’s a prototype, a personalized component, or a short-run production part, traditional manufacturing methods can be expensive, time-consuming, and limiting in design complexity. Enter commercial 3d printing services—a transformative solution that makes custom manufacturing more accessible and efficient. Here’s how 3D printing has revolutionized custom manufacturing and why it’s becoming the go-to method for businesses looking for flexibility and innovation.

1. Design Freedom and Flexibility

One of the biggest advantages of 3D printing is its design flexibility. Unlike traditional methods, where designs may be restricted by molds or tooling, 3D printing allows for the creation of complex geometries and intricate details that would be impossible with conventional manufacturing. This level of design freedom is especially valuable for custom products, allowing businesses to push the boundaries of innovation.

- Complex geometries: With 3D printing, intricate parts, such as lattice structures or organic shapes, can be produced with ease.

- Customization on the fly: Businesses can rapidly adjust designs without needing new tools or molds, making modifications quick and cost-effective.

2. Rapid Prototyping and Iteration

Speed is crucial in product development, and commercial 3D printing services excel in rapid prototyping. Businesses can quickly go from a digital design to a physical part, enabling faster iterations and more efficient development cycles. Instead of waiting weeks for a traditional prototype, companies can have a 3D-printed version in days, allowing them to test and refine their designs faster.

- Fast iterations: Quickly print, test, and modify designs based on feedback or changing requirements.

- Shorter time-to-market: Rapid prototyping accelerates product development, helping businesses get their products to market faster.

3. Cost-Effective for Low-Volume Production

For custom manufacturing, traditional methods like injection molding can be prohibitively expensive due to tooling costs, especially for low-volume production. In contrast, 3D printing eliminates the need for costly molds, making it a highly cost-effective option for producing small batches or one-off custom parts.

- No tooling costs: Unlike traditional methods, 3D printing doesn’t require expensive molds, lowering upfront costs.

- Low-volume affordability: 3D printing is ideal for businesses needing small production runs or highly customized parts without the overhead of traditional manufacturing.

4. Material Variety

Commercial 3D printing services offer a wide array of materials, from durable plastics to high-performance metals, enabling businesses to choose the right material for their custom products. Whether it’s a prototype that needs flexibility or a functional part requiring heat resistance or strength, 3D printing services provide the material diversity to meet specific project requirements.

- Plastics: Ideal for lightweight, cost-effective prototypes and functional parts.

- Metals: Suitable for high-strength, heat-resistant components used in aerospace, automotive, and other industries.

- Composites and specialty materials: Perfect for parts that need enhanced properties like electrical conductivity or chemical resistance.

5. Reduced Waste and Sustainability

Traditional manufacturing methods often involve removing material from a solid block (subtractive manufacturing), which can result in significant waste. In contrast, 3D printing is an additive process, where material is deposited layer by layer, using only what is necessary to create the part. This reduces material waste and contributes to more sustainable production practices.

- Minimized material usage: By only using the material needed, 3D printing significantly reduces waste, making it an environmentally friendly option.

- Energy efficiency: Many 3D printing processes are more energy-efficient compared to traditional manufacturing methods.

6. On-Demand Manufacturing

With commercial 3D printing services, businesses can adopt an on-demand manufacturing model, producing parts or products when they are needed, rather than relying on large inventories. This approach not only reduces storage costs but also minimizes the risk of overproduction and waste.

- Just-in-time production: Print parts as needed, avoiding large inventory holdings and reducing warehousing costs.

- Customization at scale: Offer personalized or customized products on demand without the need for separate tooling or setups for each version.

7. Scalability and Customization

Whether you need a single prototype or a thousand custom components, commercial 3D printing services provide scalability to meet your manufacturing needs. Many service providers offer options for low-volume runs, mass customization, and everything in between. This level of flexibility is ideal for businesses that require varied production volumes or frequent design changes.

- Small batch or mass production: Scale production up or down based on demand without major disruptions or cost increases.

- Mass customization: Easily personalize individual products in a production run without requiring separate tools or setups.

8. Enhanced Product Development

Commercial 3D printing services provide businesses with the ability to iterate designs quickly and optimize parts for function, weight, or cost without traditional manufacturing constraints. By testing prototypes in real-world conditions, businesses can refine designs before committing to full-scale production, reducing the risk of expensive design flaws.

- Functional testing: Create prototypes that can be tested in real-world conditions, ensuring that the final product performs as expected.

- Design optimization: Easily adjust and refine designs based on feedback or testing without starting from scratch.

9. Access to Expertise

Commercial 3D printing services offer access to expert engineers, designers, and technicians who specialize in additive manufacturing. These experts can guide businesses through the design and production process, ensuring that products are optimized for 3D printing. This can be especially valuable for companies that are new to 3D printing or need support in optimizing complex designs.

- Expert guidance: Receive professional advice on design optimization, material selection, and production techniques.

- Industry-specific solutions: Leverage the knowledge of industry experts who understand the unique challenges of your market.

10. Competitive Advantage

Leveraging the power of 3D printing services allows businesses to stay competitive by offering faster delivery times, personalized products, and lower production costs. As industries continue to evolve, the flexibility and innovation enabled by 3D printing can give your business an edge in meeting customer demands and adapting to new market trends.

- Faster response to market demands: Quickly produce new products or adapt existing ones to meet customer needs.

- Innovative products: Design and produce products that stand out from the competition due to unique features or customization.

Conclusion

Commercial 3D printing services make custom manufacturing easier, faster, and more affordable than ever before. From rapid prototyping and flexible design to reduced waste and on-demand production, 3D printing offers a wealth of benefits for businesses looking to innovate and stay ahead in today’s competitive market. By leveraging these services, companies can unlock new possibilities in product design, streamline manufacturing, and ultimately provide better, more tailored solutions for their customers.